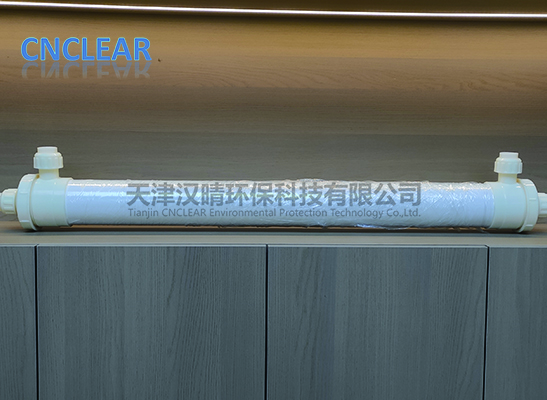

This is a customized hollow fiber membrane we developed for a client. While our standard 4-inch membrane modules are typically designed as PES-based and internally pressurized, this version has been customized to be PVDF-based and assembled in an externally pressurized configuration. This ultrafiltration membrane is applied in the final ultrafiltration stage of ultrapure water treatment processes, with the product water directly used as process water.

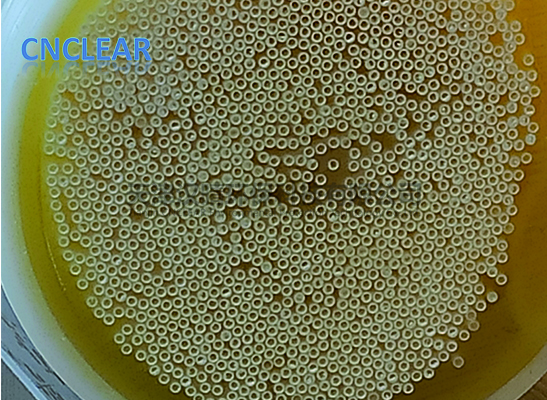

This end is the feed water inlet. Water enters the interior of the membrane module through the central tube—here, "interior" actually refers to the space between the membrane fibers. Under pressure, water permeates from the outer wall of the membrane fibers to the inside of the fibers. The product water is then discharged through the two outlets at the product water end of the module for subsequent use or treatment. Water that does not pass through the pores of the membrane fibers (i.e., water containing retained contaminants, also referred to as concentrate or retentate) is discharged from the other end of the module and usually requires further treatment or disposal.

In this design, the feed pressure is applied to the outside of the membrane fibers, while the permeate (i.e., product water) flows out from the inner wall of the fibers. This configuration helps reduce membrane fouling, as most contaminants are retained on the outer surface of the membrane fibers and can be easily removed through methods such as backwashing.

Inquire immediately